What material do you need cutting?

Waterjet cutting is suitable for a wide range of materials:

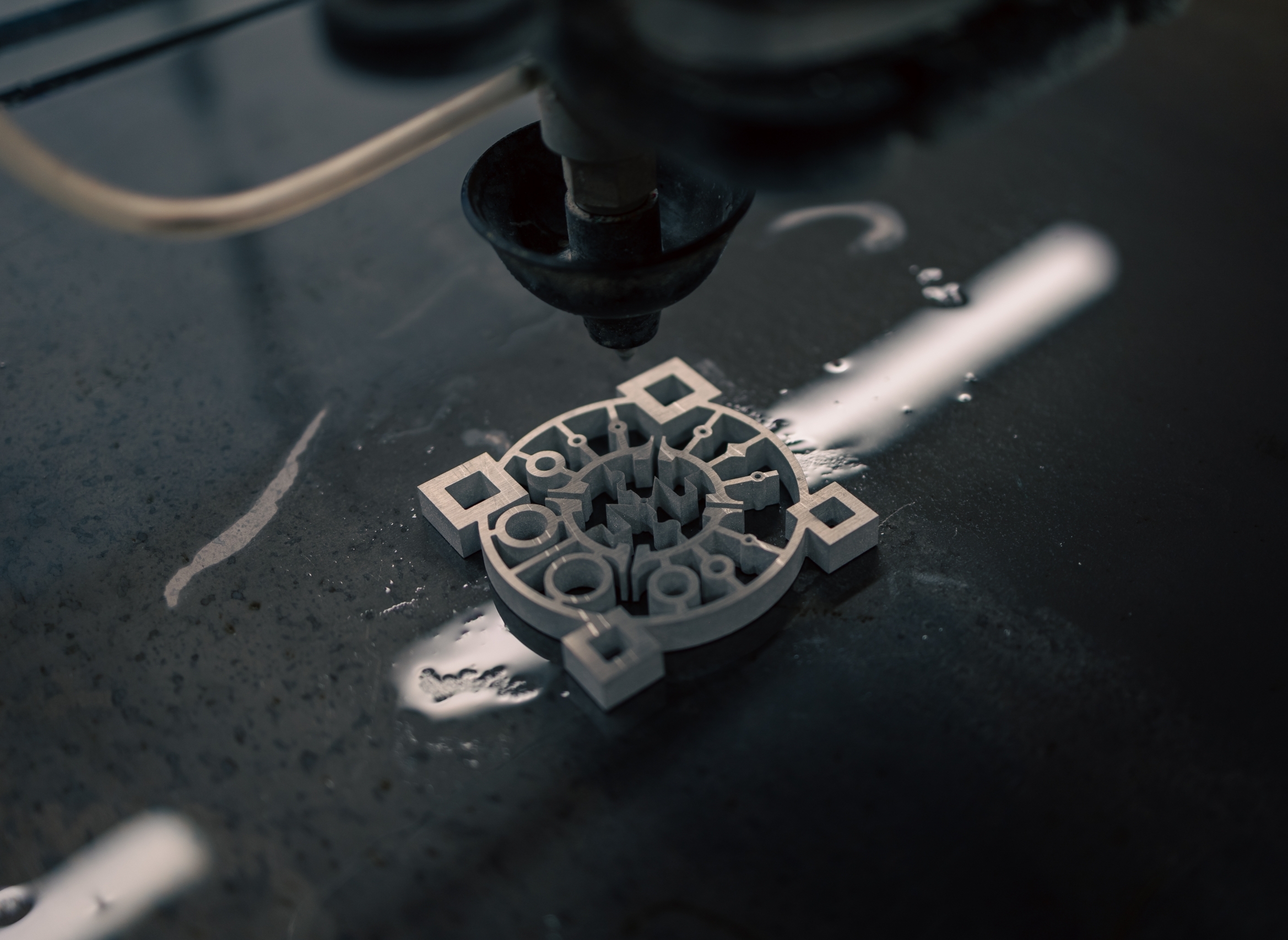

How does waterjet cutting work?

A series of steps to a perfection cut, on most materials.

Water

Pressure

Abrasive Substrate

Why Choose Waterjet Cutting?

Waterjet cutting technology offers superior efficiency for a wide range of manufacturing jobs. It can cut everything from metal and plastic to stone, wood, and ceramic. In fact, it’s able to cut almost anything with precision accuracy – apart from tempered glass and diamond. It also gives the cut product a smooth, clean edge quality when finished, while always remaining cost-effective.