Our Services

What We Do

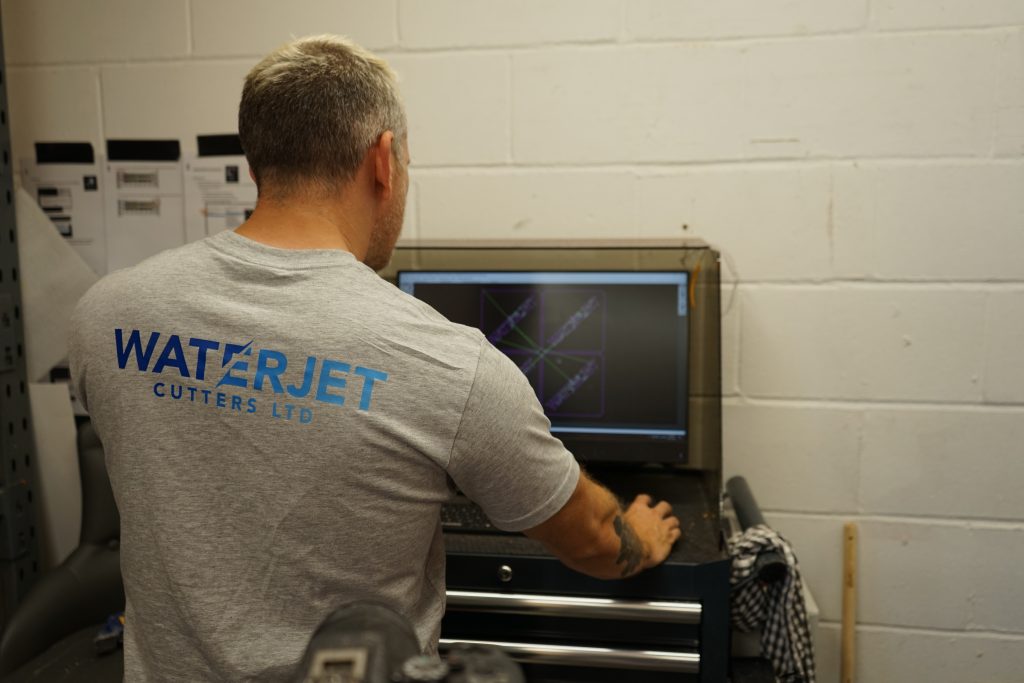

We utilise the knowledge and skills of over 20 years in the business to provide high-quality, versatile waterjet cutting. These services have been moulded to meet all manufacturing and design needs and specifications, no matter what you want from the result.

We’ve also recently expanded our business operations, investing in state-of-the-art waterjet and abrasive cutting technology. This is the machinery that’s pioneering the modern market, meaning you’ll always be afforded the best finish from the cutting process.

By fusing our team’s expertise with OMAX’s most recent dynamic head waterjet technology, we are able to provide profiling services that can be customised for each client. Get precision cutting performed to industry standards, and that exceeds your expectations.

How it Works

Waterjet cutting is an accelerated manufacturing process involving erosion. It begins when an extremely high-pressure jet of water is fired through a nozzle into the machine’s mixing chamber.

The pressure involved in this creates a vacuum, drawing garnet sand into the stream. This is then fired at the material you’ve chosen for precision cutting. The sand particles eat away at the material, eroding it until it’s cut into the dimensions you’ve requested.

Materials We Can Cut

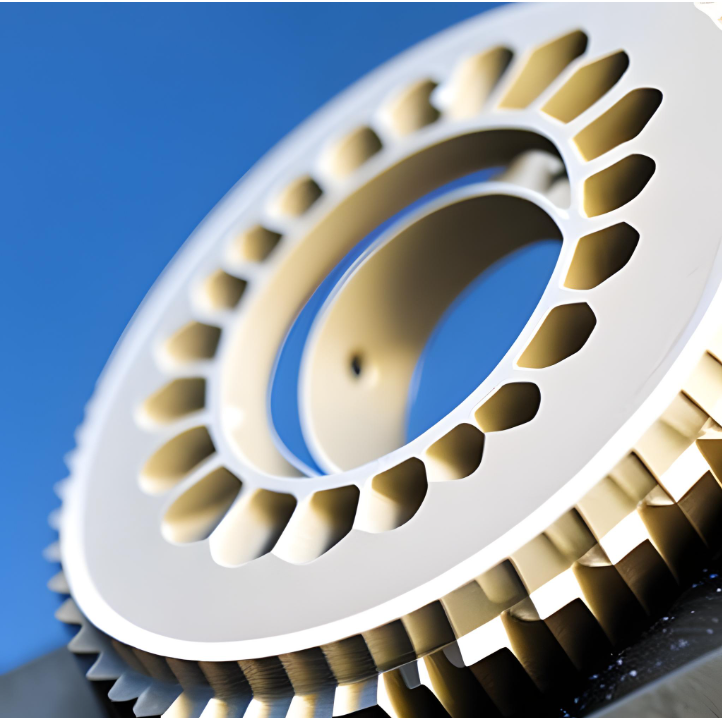

Metal

As a cold cutting process, it’s ideal for metal. No heat staining and no secondary finishing.

Synthetic

Synthetic and composite materials are easily cut to accurate measurements without losing strength.

Plastic

The absence of heat ensures plastic retains structural integrity. No toxic fumes are released, either.

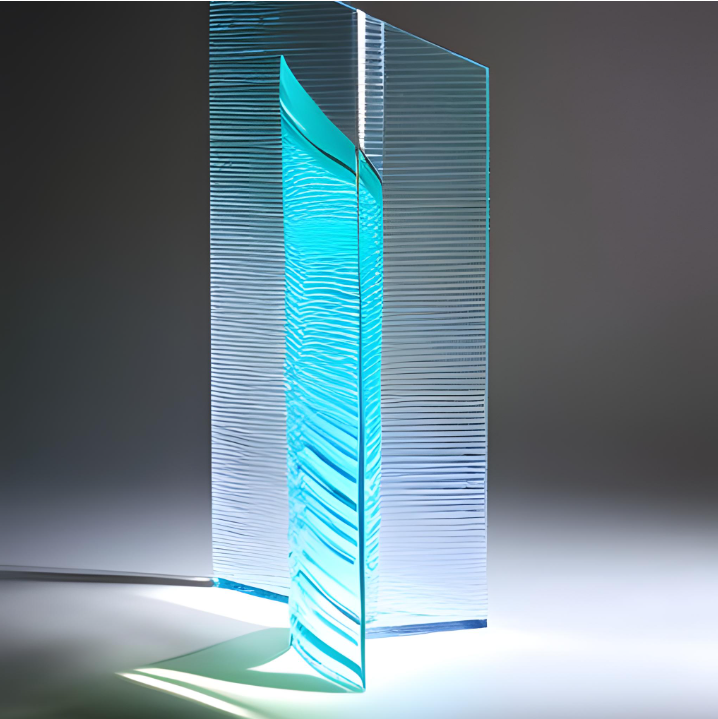

Glass

It’s the most cost-effective way of processing full pieces of glass. It’s also the fastest method.