About Us

We’re dedicated to providing exceptional waterjet cutting services, having built these up into a flawless process over the years we’ve worked in the industry. But how did we start? Let us tell you more.

Your Professional Precision Cutters

We’re proud to have expertise in our industry stretching back to 2004, even though our sister company (Designs & Lines Ltd.) was first established in 2011. This began, first and foremost, with cutting plastics for top-quality designs and sharp, clean manufacturing finishes. By expanding our capabilities and upgrading our technology to the latest available, we’ve since seen consistent, sustainable success and continued growth into the present day.

This isn’t all down to our perfected cutting process, either. We may have honed our skills in the time we’ve worked to ensure a flawless, precision-accurate cut with every product, but business goes beyond the basics of selling. We also make it our mission to get to know the people we’re working with, forging long-lasting beneficial working relationships as we do. Whenever you decide that we’re the team you need for top-quality waterjet cutting services, you’re guaranteed a good working partnership from the start.

You won’t be the only business looking for what we can offer, either. Waterjet cutting has taken off in popularity for all kinds of industries and their design and manufacturing processes. Implementing a strategy of continuous improvement has worked well for us in this, as it means we’ve invested in just the right technology at just the right time – exactly when we’re needed most. Moulding our business operations around this strategy has then meant we’ve been able to triple our capacity in relatively short order.

The result of all of this? We’re now able to accurately profile ferrous, non-ferrous, nickel alloys, and other materials, while cutting in greater volume than ever before. For every business we work with in every industry we cover, this has meant a sharp increase in efficiency via reduced lead times. Down the line, this is bound to translate into saved money and resources, making the whole process more cost-effective for your business.

Where We Work

We’re happy to offer waterjet cutting services across a broad range of markets and industries – including niche sectors in need of intricate design work. No matter which you work in, we’ll do everything we can to ensure you receive the accurate and precise waterjet cutting services you need to move forward with your work project.

From working alongside tradespeople, to working as a subcontractor for large construction companies, to being called to take part in aerospace projects, we have done it all. We’ll also be glad to do it again for you, if this is what your work requires. All you need to do is get in touch and let us know what you would like from our services.

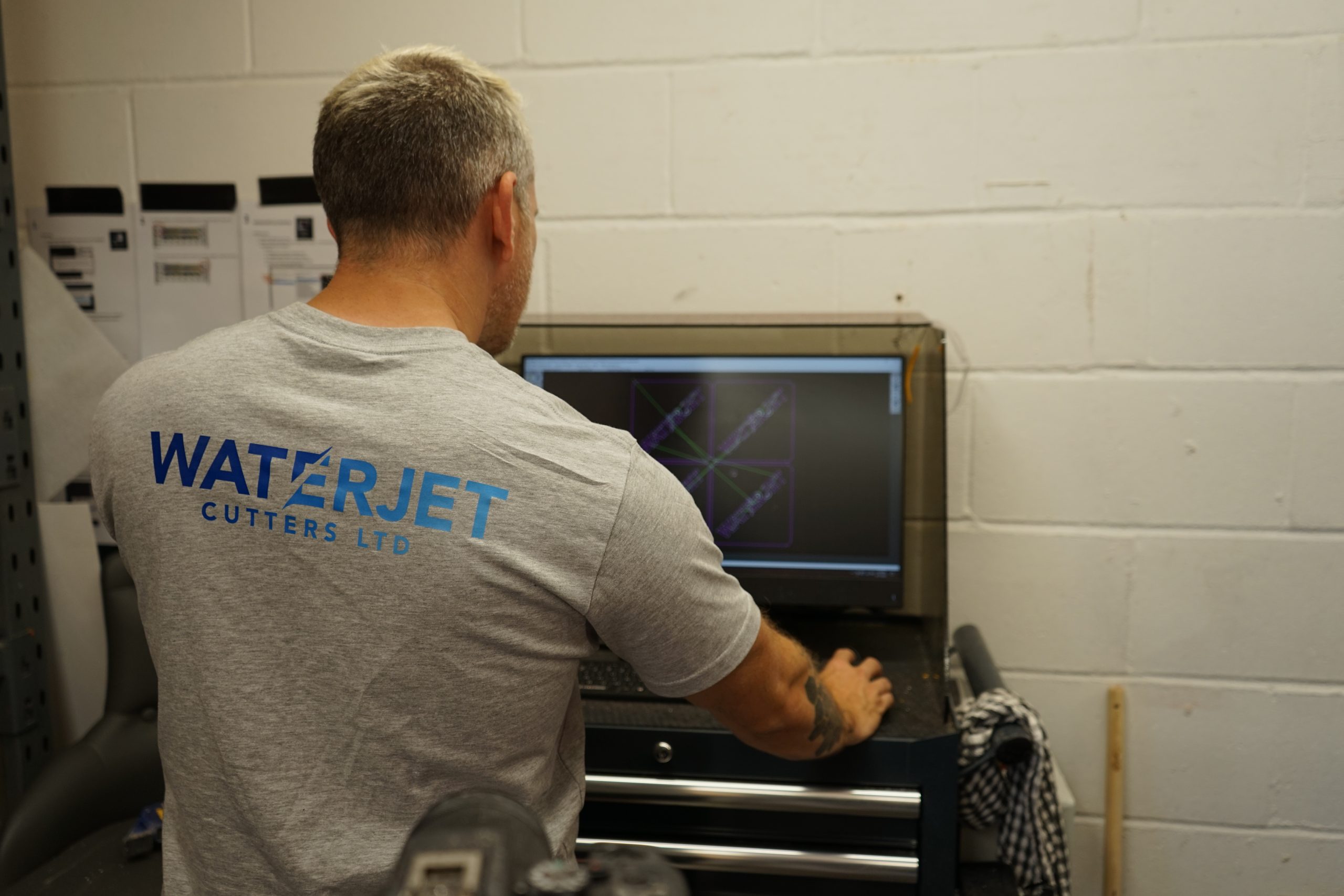

Our Team

Our fantastic team will be on hand to help throughout the process of ordering and manufacture. They’ll do everything they can to ensure you receive the exact product you’ve asked to be cut, no matter the size or scope of pieces themselves. They take pride in working closely with clients to produce pieces, whether clinical and clean for practical uses or complex and creative for aesthetic appeal. You’ll get to find out just how much when you speak to them.

Eco

Friendly

Environmentally-friendly procedures are getting more significant and more necessary across all business types. Unlike other cutting methods, waterjet cutting does not produce any hazardous waste in the form of fumes or gases.

Wide Range of Materials

Waterjet cutting is an ideal cutting method for a range of materials, including metal, plastic, wood, glass, stone, composite, ceramic, and acrylics. It’s guaranteed to cut through almost anything, apart from tempered glass (which would shatter) and diamond (which is too hard).

No Thermal

Damage

Unlike other cutting processes, waterjet cutting doesn’t produce heat. This is called a “cold-cutting” method. By using one we avoid the creation of a heat-affected zone (HAZ), preventing thermal distortion in a material. The result is a smooth, burr-free cut.

Why Use Waterjet Cutting?

There are many reasons we offer, and you should use, waterjet cutting to complete your design and manufacturing work. However, they all have one common theme in the end: efficiency. The versatility, flexibility, and accuracy of the process ensures faster, more cost-effective, and easier production of the pieces you want. In turn, more time, money, and resources are saved. The quality of the process itself also means that the products produced are of a superior quality.

Find out more about the benefits of waterjet cutting below.